SUSTAINABLE TERRA-COTTA AIR EVAPORATIVE COOLING SYSTEM (STAEC)

PROBLEM

In the UAE, summer temperatures can exceed 40°C (104°F), creating serious problems for low-income workers in crowded areas. Their housing often lacks affordable cooling, leading to uncomfortable and unsafe conditions.

Shocking fact

The U.A.E. HVAC market is projected to grow from $1,873.1 million in 2019 to $2,774.7 million by 2030, driven by increased infrastructure investments in commercial, industrial, and residential sectors, and the growth of the tourism industry.

BACKGROUND RESEARCH

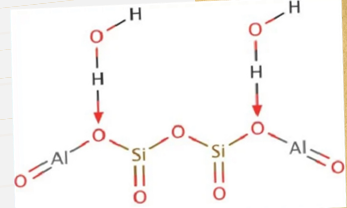

Terracotta is a mixture of many compounds with clay-like properties. Different clays vary in chemical composition. Terracotta minerals,like all phyllosilicates, feature two–dimensional sheets of SiO4 tetrahedra or AlO4 octahedra with the formula (Al, Si)3O4. Each silica tetrahedron shares three oxygen ions with others, forming a hexagonal array.

Background Research

In the ancient world, terracotta was used for bricks, roof tiles, and decorating . Greek artists brought this craft to Etruria around 3000 BCE, and later, Etruscan and Greek sculptors worked it in Rome.

HYPOTHESIS

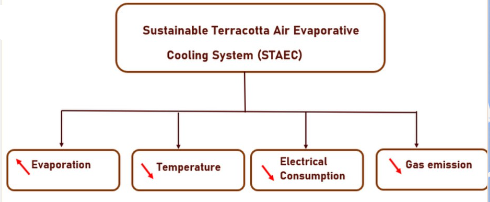

The Sustainable Terracotta Air Evaporative Cooling System (STAEC) uses terracotta to cool houses by 60-70% without electricity. It reduces monthly electricity use by 50-60% and cuts gas emissions by 40-50%, making it eco-friendly and sustainable.

PROCEDURE

- – Create solid and hollow bricks in three sizes (10×9 cm, 20×9 cm, 28×16 cm) and three thicknesses (0.3 cm, 0.5 cm, 1 cm).

– Bake in a kiln at 220°C:

– 1st step: 8 hours

– 2nd step: 12 hours

- – Construct two identical acrylic incubators – Install the bricks vertically on the interior walls.

3.- Install a thin pipe with small holes to drip water directly on the bricks, creating a wet environment.

4.- Install heat sensors inside each incubator.

– Heat each incubator with identical bulbs until the temperature

reaches 29°C.

– Turn off the heat bulbs and continuously monitor the temperature.

– Record temperature every hour.

- – Compare temperature data from each incubator to determine the best terracotta design for thermal regulation.

EXPERIMENTATION

T 1

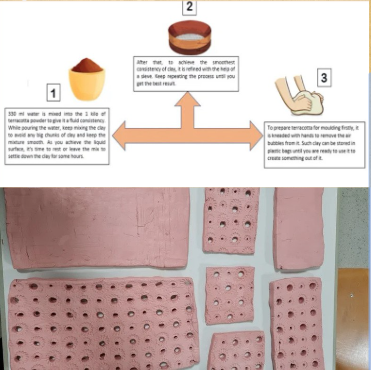

- We created two kinds of red Terracotta blocks: a solid brick and a hollow brick.

- First, we did not put the accurate amount of water to mix it with the terracotta powder.

- And the hollow brick wasnt tidy, no mold just making holes. In addition, we baked both blocks in the kiln for just 2 hours. Next, we connected the heat sensors to monitor the temperature.

T 2

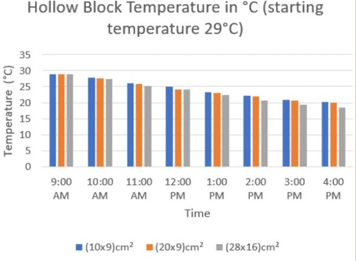

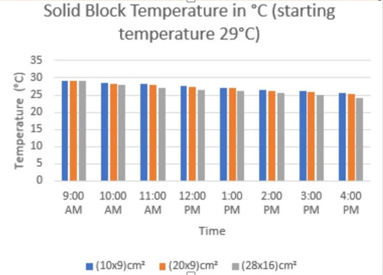

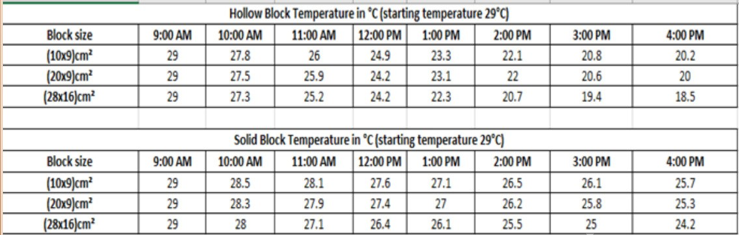

We created different designs (Solid bricks and hollow bricks) out of Terracotta with different sizes We wanted to observe the effect of the two factors; size and thickness on the evaporation process as well as the reduction of the interior temperature.

T 3

So, the fixed variable here was the baking time and temperature. We used the same kiln with the maximum temperature 220 Celsius degree through 2 steps. In the 1st baking process (we put the bricks inside a kiln for 8 hours). The 2nd step we put the bricks in a kiln again for 12 hours (2nd baking process) to give the terracotta molds strength and durability.

DATA ANALYSIS

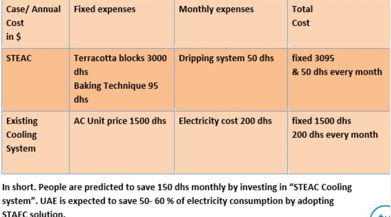

Comparing the effect of the thickness for both types of blocks (solid and hollow) on the temperature of the incubators in tables and graphs , and comparing the cost between (STAEC) and the normal cooling systems

IMPACT

Positive impacts of Terracotta Air Evaporative Cooling Systems:

1.Less Electricity Use:

Terracotta cooling saves energy by not needing electricity like traditional AC systems

2. Reduced Greenhouse Gas Emissions.

These systems cut greenhouse gas emissions by not relying on electricity, especially important in areas with

dirty energy sources

3.Eco-friendly materials:

Terracotta is made from natural clay, using less energy to produce and causing no harm to the environment.

SDGs

Our project is connected with 2 of the Sustainable Development Goals which are :

- No. 7 : Affordable and clean energy

- No. 11 :Sustainable cities and communities

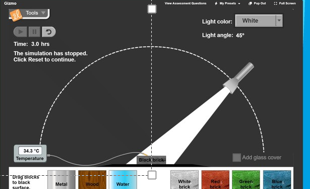

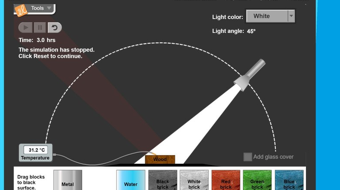

GIZMOS

And using Gizmos we determined which material is the best for building the incubators.

CONSLUSION

Sustainable Terracotta Air Evaporative Cooling System (STAEC) use terracotta’s evaporative cooling abilities to regulate temperatures naturally without requiring any electricity or complex electronics, without gas emission, and without wasting of fresh water.